THERMAL

POWER PLANT STRUCTURES LIST

|

1

|

WEIGH BRIDGE ( 100 TON )

|

2

|

WAGON TIPPLER COMPLEX -A

|

3

|

WAGON TIPPLER COMPLEX -B

|

4

|

JUNCTION TOWER- 1

|

5

|

JUNCTION TOWER- 2

|

6

|

CRUSHER HOUSE

|

7

|

JUNCTION TOWER- 4

|

8

|

JUNCTION TOWER- 5

|

9

|

COAL CONVEYOR

|

10

|

CRUSHER COAL STOCK PILE -A

|

11

|

CRUSHER COAL STOCK PILE -B

|

12

|

CRUSHER COAL STOCK PILE -C

|

13

|

CRUSHER COAL STOCK PILE -D

|

14

|

PENT HOUSE -2

|

15

|

JUNCTION TOWER- 6

|

16

|

JUNCTION TOWER- 7

|

17

|

EMERGENCY RECLAIMING HOPPER COMPLEX

|

18

|

PENT HOUSE -3

|

19

|

JUNCTION TOWER- 9

|

20

|

JUNCTION TOWER- 10

|

21

|

JUNCTION TOWER- 11

|

22

|

JUNCTION TOWER- 12

|

23

|

JUNCTION TOWER- 13

|

24

|

DRIVE HOUSE-1

|

25

|

DRIVE HOUSE-2

|

26

|

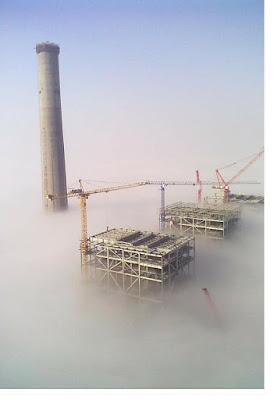

BULDOZER SHED

|

27

|

COAL SHETLING POND

|

28

|

STACKER/RECLAIMER

|

29

|

CHP ELECTRICAL BUILDING-1

|

30

|

CHP ELECTRICAL BUILDING-2

|

31

|

CHP ELECTRICAL BUILDING-3

|

32

|

CHP ELECTRICAL BUILDING-4

|

33

|

CHP PUMP HOUSE-2

|

34

|

CHP PUMP HOUSE-3

|

35

|

CHP PUMP HOUSE -1

|

36

|

PENT HOUSE -1

|

37

|

LDO UNLOADINF & SUPPLY PUMP HOUSE

|

38

|

GENERATOR TRANSFORMER

|

39

|

UNIT AUXILIARY TRANSFORMER

|

40

|

STATION TRANSFORMER

|

41

|

SERVICE BUILDING

|

42

|

CONDENSATE STORAGE TRANSFER PUMP

HOUSE

|

43

|

CONDENSATE STORAGE-A

|

44

|

CONDENSATE STORAGE-B

|

45

|

AMONIA STORAGE

|

46

|

FIRE WATER BOOSTER PUMP HOUSE

|

47

|

AIR COMPRESSOR & MILL REJECT

COMPRESSOR BUILDING

|

48

|

DG AREA

|

49

|

HYDROGEN GENERATION PLANT

|

50

|

N2 BOTTLE AREA

|

51

|

400KV GIS BUILDING

|

52

|

765KV SWITCHYARD BUILDING

|

53

|

765KV AIS SWITCHYARD CONTROL BUILDING

|

54

|

SPARE TRANSFORMER

|

55

|

AUXILIARY TRANSFORMER

|

56

|

CEMS

|

57

|

AUXILIARY BOILER CONTROL BUILDING

|

58

|

AHP COMPRESSOR HOUSE

|

59

|

ASH SLURRY SUMP

|

60

|

ASH SLURRY PUMP HOUSE

|

61

|

AHP VACCUM PUMP HOUSE UNIT -1

|

62

|

AHP VACCUM PUMP HOUSE UNIT -2

|

63

|

AHP COMPRESSOR & VACUUM PUMP ELECTRICAL ROOM

|

64

|

ASH WATER PUMP HOUSE &

ELECTRICAL /CONTROL BUILDING

|

65

|

ASH WATER CLARIFLOCULATOR-A

|

66

|

ASH WATER CLARIFLOCULATOR-B

|

67

|

ASH WATER CHEMICAL HOUSE

|

68

|

INTERMEDIATE SILO- A

|

69

|

INTERMEDIATE SILO- B

|

70

|

TERMINAL SILO UTILITY BUILDING

|

71

|

TERMINAL SILO-A

|

72

|

TERMINAL SILO-B

|

73

|

TERMINAL SILO-C

|

74

|

TERMINAL SILO-D

|

75

|

HCSD & ENTERMEDIATE SILO UTILITY

BUILDING.

|

76

|

HCSD PUMP HOUSE

|

77

|

HCSD SILO -A

|

78

|

HCSD SILO -B

|

79

|

ASH WATER MAIN ELECTRICAL /

CONTROL BUILDING

|

80

|

EMERGENCY RAW WATER PUMP HOUSE

|

81

|

AUXILIARY BOILER

|

82

|

AUXILIARY BOILER LDO STORAGE TANK

|

83

|

Boiler Foundation /#1 & #2

|

84

|

MIIL BAY

|

85

|

ELECTROSTATIC PRECIPITATOR

|

86

|

ESP CONTROL BUILDING UNIT-1

|

87

|

ESP CONTROL BUILDING UNIT-2

|

88

|

FGD ABSORBER FOR UNIT 1

|

89

|

FGD ABSORBER FOR UNIT 2

|

90

|

FGD ABSORBER RECIRCULATION PUMP

SHELTER FOR UNIT- 1

|

91

|

FGD ABSORBER RECIRCULATION PUMP

SHELTER FOR UNIT- 2

|

92

|

GYPSUM DEWATERING BUILDING

|

93

|

GYPSUM SHED

|

94

|

FGD FILTRATION TANK &

AGITATOR

|

95

|

LIME STONE UNLOADING HOUSE

|

96

|

LIME STONE PREPARATION BUILDING

|

97

|

LIME STONE SILO

|

98

|

LIME STONE SLURRY STORAGE TANK

& AGITATOR

|

99

|

FGD EMERGENCY STORAGE TANK &

AGITATOR

|

100

|

FGD MAKE-UP WATER TANK

|

101

|

FGD WASTE WATER TREATMENT

BUILDING

|

102

|

FGD ELECTRICAL BUILDING

|

103

|

LIMESTONE CRUSHER BUILDING

|

104

|

LIMESTONE CONVEYOR PENT HOUSE

|

105

|

CHIMNEY

|

106

|

CLARIFIED WATER RESERVIOR-A

|

107

|

CLARIFIED WATER RESERVIOR-B

|

108

|

RAW WATER PUMP HOUSE

|

109

|

PRE-TREATMENT BUILDING

|

110

|

PRE-TREATMENT CLARIFIER -A

|

111

|

PRE-TREATMENT CLARIFIER -B

|

112

|

PRE-TREATMENT CLARIFIER -C

|

113

|

CMB

|

114

|

CLARIFIED/ FIRE WATER PUMP

HOUSE& FIRE WATER RESERVIOR

|

115

|

DM PLANT AREA INCL. CHEMICAL STORAGE & CPU REGEN.

|

116

|

DM WATER PUMP HOUSE

|

117

|

DM STORAGE TANK -A

|

118

|

DM STORAGE TANK -B

|

119

|

CW CHLORINATION BUILDING

|

120

|

SIDE STREAM FILTRATION PLANT

|

121

|

CW PUMP HOUSE

|

122

|

EFFLUENT TREATMENT PLANT AREA

|

123

|

EFFLUENT TREATMENT PLANT

CLARIFIER

|

124

|

Mill Reject Silo

|

125

|

FUEL OIL STORAGE TANK-A

|

126

|

FUEL OIL STORAGE TANK-B

|

127

|

LDO PRESSURIZING PUMP HOUSE

|

128

|

FUEL OIL DAY TANK-A

|

129

|

FUEL OIL DAY TANK-B

|

130

|

Turbine Generator Building .

(Only CW,CEP pit) #1 & #2

|

131

|

CENTRAL CONTROL BUILDING

|

132

|

COOLING TOWER FOR UNIT-1

|

133

|

COOLING TOWER FOR UNIT-2

|

134

|

COOLING WATER INTAKE CHANNEL

|

135

|

COOLING TOWER SWGR & CONTROL

BUILDING

|

136

|

SEWAGE TREATMENT AREA

|

137

|

WASTE WATER TREATMENT ELECTRICAL

ROOM

|

138

|

FIELD QUALITY CONTROL BUILDING

|

139

|

FIRE STATION BUILDING

|

140

|

STORAGE YARD AREA

|

141

|

STORAGE YARD BUILDING

|

142

|

WORK SHOP BUILDING

|

143

|

WEIGH BRIDGE FOR FLY ASH SILO (

40TON )

|

144

|

RAIN WATER HARVESTING POND

|

145

|

PARKING SHED

|

146

|

PIPE RACK

|

147

|

FOAM PUMP HOUSE FOR FUEL OIL DAY

TANK

|

148

|

FOAM PUMP HOUSE FOR FUEL OIL

STORAGE TANK

|

.jpeg)

Comments

Post a Comment

If you have any suggestions and doubts please let me know.